As F&B manufacturers handle various levels of ingredients, it is important to recognize that common food allergens such as tree nuts can make their way into products. To ensure the safety of millions of consumers, the Food Allergen Labeling and Consumer Protection Act (FALCPA) was implemented in 2006. The purpose of FALCPA was to provide improved food labeling information, which is especially crucial for those with food allergies. By clearly identifying potential allergens on product labels, F&B manufacturers can help prevent serious allergic reactions and keep consumers informed and safe.

Isolating Food Allergens

82% of recalls are from wrong packaging or false labels (CDC).

In the event of an allergen contamination recall, the ability to isolate the allergens is critical. An ERP solution gives you the ability to forecast to what level of products has been affected, including which items have been contaminated, their origination and destination.

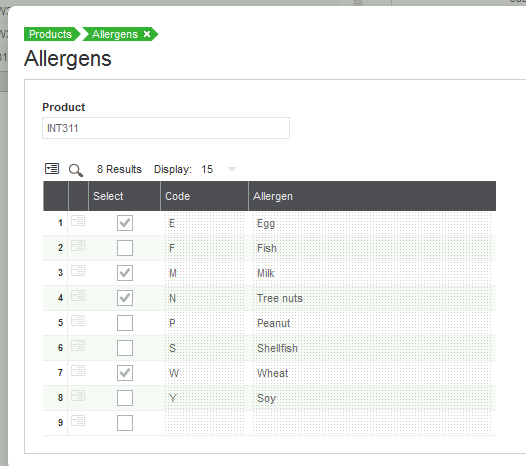

Below is a screenshot of how Sage X3 can isolate allergens in a product rollup.

Process and Reporting Transparency

When it comes to transparency for F&B companies, allergen tracking is at the top of the list. With an estimated 15 million American’s having food allergies, it is imperative that F&B facilities have a way to track allergens, store them, account for their use in end-products to avoid recalls of undeclared allergens.

Watch a video on Allergen and Constraint functionality in Sage X3.

This is the 3rd step of 7 in weekly blog series 7 Steps to Transparency for Food and Beverage Manufacturers, does your company have the proper tools in place to meet new regulations?

Download the infographic today.