Can you trace where your ingredients have been?

In the push to be more transparent food and beverage (F&B) manufacturers need to be able to quickly track ingredients both forward in production and backwards to the original source, throughout all the process stages and quality checks until it is delivered to the consumer.

Traceability is defined by the Global Food Traceability Center as, the ability to access any or all information relating to that which is under consideration, throughout its entire life cycle, by means of recorded identifications. How are you recording where they received a product from, and its movement throughout the supply chain?

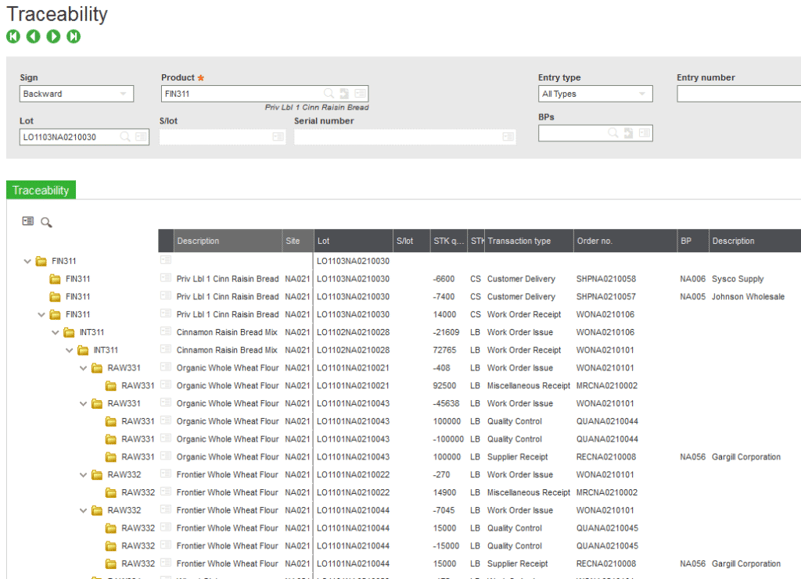

A modern ERP solution such as Sage X3 shown below should be able to trace ingredients and final goods up and down the supply chain from farm to fork. The screen shot also pinpoints the transaction type through the supply chain and assigns ownership.

Traceability should not be confused with a recall plan. Traceability within a business management solution gives the user the ability to quickly determine where an ingredient came from and where it was sent out to. Learn how this process can be completed within 4 minutes with the proper ERP software solution, contact RKL eSolutions.

This is the 2nd step of 7 in weekly blog series 7 Steps to Transparency for Food and Beverage Manufacturers, does your company have the proper tools in place to meet new regulations? Download the infographic today.