Sean Riley, Director of Supply Chain Innovation for Software AG and writing for Supply Chain Management Review, recounted some of the supply chain trends that shaped 2012. In doing so, he began by pointing out that as supply chain technologies continued to evolve in 2012, more and more companies realized the inevitable fact that supply chain visibility was the key factor and necessity “for success in today’s business economy.”

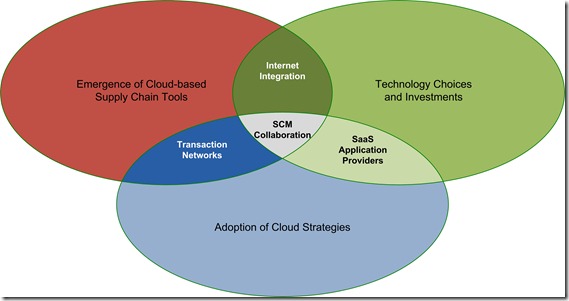

It is the fortunate emergence of cloud-based supply chain tools and the increasing willingness of enterprises to adopt cloud-based strategies that is beginning to make near real-time supply chain visibility and broader collaboration possible for small to mid-sized business manufacturers and distributors. Of course, the third piece that must fall in place in order to allow SMEs (small to mid-sized enterprises) to begin to compete on a more level playing field with the Fortune 1000 competitors is now their technology choices and their willingness to invest in these new supply chain alternatives.

In fairness to SME executives and management, however, it should be noted that many of the existing collaboration tools are priced in such a way that it makes it very difficult for the small enterprise to even consider making the technological leap into true supply chain collaboration. As a result, the executives and owners in these organizations frequently feel trapped into rudimentary file-sharing or other archaic methods of data sharing.

Many of these SMEs may see the value of end-to-end supply chain visibility and exhibit a heartfelt desire to participate in secure data flows between collaborative partners; however, they lack the information technology assets to build the linkages themselves. Also, they do not feel that they can afford to make the large cash outlays required to begin participating in many of today’s existing collaborative networks—especially in today’s tough economic climate.

As a result, these organizations frequently feel “stuck.” At the mercy of a supply chain in which they are essentially “blind”—with little or no visibility into timely or accurate data on either inbound supplies or end-user demand—they attempt to do battle with their formidable competitors with the only tools they have available to them:

- Cost-cutting – They are seeing more and more that cost-cutting is beginning to affect their ability to recover from the inevitable (even if occasional) blows from “Murphy.” They know that they must improve customer service levels if they are to remain competitive in their supply chain environment, but cost-cutting is continually undermining their capabilities to do so.

- Demand and supply chain forecasting and planning – The executives and managers are seeing almost every day the disheartening effects of the old adage “Every forecast is wrong—only the ‘how much’ varies.” Increasing market volatility made all the more damaging by shorter and shorter product life-cycles is creating a world where forecasting and planning fall far short of the desired ends. What they desperately need is improved execution, but in the absence of near real-time visibility upon which to act, they do not know how to make their execution effective in producing improved profits.

- “Big Data” – Many of these organizations are making investments in “big data” and business intelligence tools in order to try to make up for their lack of visibility across the supply chain. Unfortunately, having more data and analyzing more data (i.e., big data) is of little help when what you need is fast data. Fast data—near real-time data collected from across your supply chain—will beat “big data” every time when it comes to producing profits.

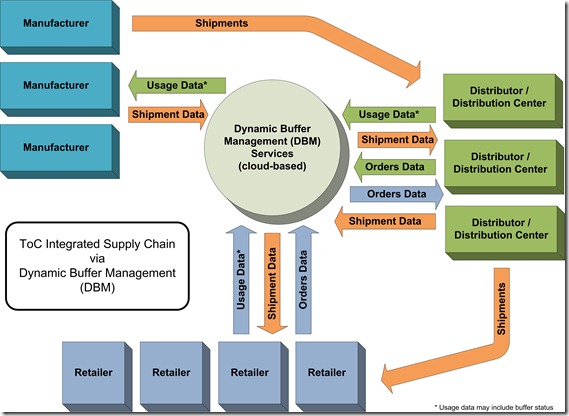

We are working on cloud-based supply chain collaboration solution concepts for small to mid-sized business enterprises. Let us know your needs and ideas.

Contact us with your comments or questions.