A new year is coming up. Time for more New Year's resolutions and goal setting.

You and your supply chain will face a fresh set of challenges in 2017. We know it can be hard to decide what your focus should be when thinking strategically about your supply chain.

You've made some decisions

You and your team have met. Driven by a review of the big challenges you faced this last year, and—in no small part by signals from the board of directors and shareholders—your company has come up with the following list of top-level goals and results targets:

- Maintain on-time shipping performance (customer service levels) at or above 95 percent

- Reduce to and hold inventory financial investment to no more than N days inventory on-hand (DOH)

- Improve critical supplier on-time delivery time to an average of greater than 85 percent

- Reduce lead-times for the top N percent of products we sell by Y percent

- Cut total cost of in-bound and out-bound logistics by N percent when compared to previous year

See Also: How to set SMART Goals for Supply Chain Improvement

What happens next?

In this article, we could ignore what happens in most companies about the time these goals get published to the rank-and-file of the organization. We could just go on to talk about theoretical tactical planning to achieve these goals that will be put on paper and handed upstream to the C-suite. We could list things like…

- Develop individual personal development plans for each member of the supply chain management team

- Develop in-house or add personnel with advanced project management skills and certifications

- Conduct fresh ABC analyses with all critical suppliers to reset min/max stocking levels and tactics for lead-time reductions

- Create and implement new (reduced) production batch-sizes to aid in the reduction of lead-times

- And so forth…

Wow! Tactics aligned to our strategies! We are all set to rock-and-roll!

This makes us sound like a real business enterprise—in your dreams or on TV!

Forget about the fact that there is no actual or meaningful correlation between the tactics suggested above and the goals being promulgated to the organization. Just forget about that.

What really happens next, when these types of goals get set in most business enterprises, is the grumbling starts.

"What the heck? Who told them we could maintain 95 percent customer service levels on only N dollar-days of inventory? We have 20 additional dollar-days on-hand now, and we're barely keeping our promises to our customers!"

"We've talked with our key suppliers for three years in a row now, and we haven't seen any real or consistent improvements in average lead times. What makes them think it will be different this time?"

"What do you mean cut total logistics costs by N percent?!? How the heck do they think we're able to keep our customer service levels so high? They can't have it both ways! It's just not fair."

"Sure! It's fine for those guys to hand down these kinds of goals. They don't have to figure out how to get it done. These just aren't realistic. I don't even feel like trying, since I know we can't make them happy."

Here is the problem

The achievement of high customer service levels, lowest optimal inventories, high levels of on-time performance by your suppliers, reduced lead times, and lowest (optimal) logistics costs are not achieved by setting goals and measuring progress against them.

Very few companies achieve success this way.

Why?

Because setting goals like these and measuring progress against them is like a baseball team manager trying to manage his team by watching the scoreboard or league standings.

It's the little things that count

The baseball team manager needs to see, measure and manage the little things like on-base percentage, which means coaching his team on managing the strike zone when they're at the plate.

If he pays attention to—and measures—the little things, odds are he will see better results on the scoreboard, as well.

Year after year, Toyota achieves all of these "goals":

- Extremely high customer service levels

- Very low inventories

- Well above-average vendor delivery performance

- Below-average lead times for their industry

- Below-average total logistics expenses

They achieve these results with almost unequaled consistency. But they don't do it by setting goals in the boardroom and promulgating them to the shop floor.

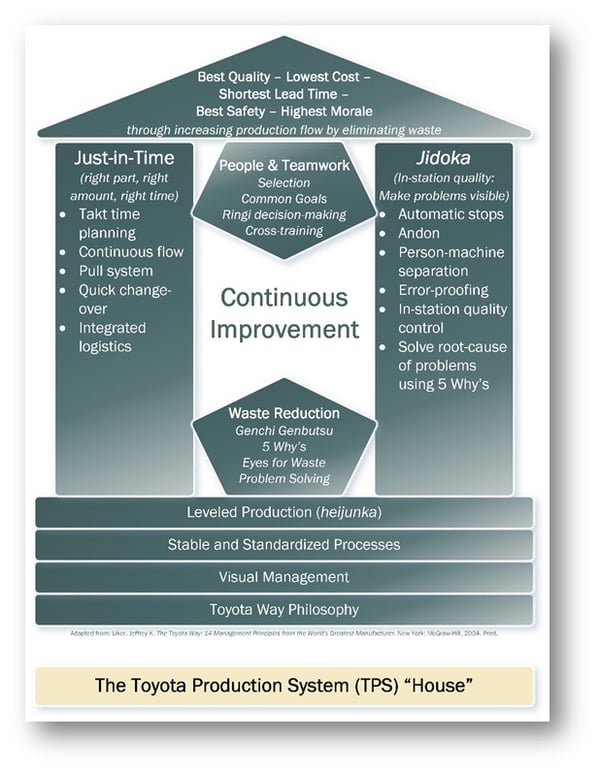

Instead, they achieve these lofty "goals"—and are profitable—by building their whole "house" with a very singular focus: FLOW.

Everything at Toyota is focused on assuring that nothing in the supply chain hinders the flow of product to their customers.

Here's the truth: Having the lowest inventory levels while achieving high customer service levels and better than average lead-times is a result of six crucial and interdependent factors:

- Producing only to actual demand (this does NOT mean make-to-order)

- Governing production and the release of materials by the rate set by the system's constraint(s)

- Reasonably buffering the constraint(s) to assure that they are never starved

- Maximizing the uptime of the constraint(s)

- Procuring materials so that the gating processes are not delayed (leading to starvation at a constraint)

- Ensuring the reliability of all processes that support buffers at the constraint(s)

What do all of these crucial processes do?

Support FLOW. That's it.

Learn how to take charge of these matters—that is, how to configure and maintain metrics that (like the baseball team manager) keep your supply chain team focused on the few tiny things that lead to more wins—and your team will also achieve the grander top level goals that keep the folks in the C-suite happy.

We can help you learn the strategies and tactics that will help you get to your goals. Contact us for more information.