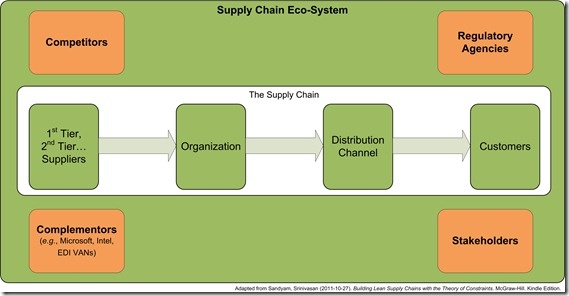

The Basic Supply Chain Eco-system

It looks something like this:

What makes it so difficult to build a solid foundation of collaboration between the supply chain participants? And what makes it even more difficult to sustain high levels of cooperation and collaboration between and among the participants?

If you’ve had any experience with attempting this, you probably already know the answer.

“It’s simple,” I hear you saying. “Everyone in the supply chain is looking out for themselves and when push comes to shove, they’re going to do what’s best for their own company, regardless of what happens elsewhere in the supply chain.”

This, of course, is true.

I’ll go even further. Not only is it true but, because I want it to hold true for my company, I’ll be fair and say that it ought also remain true for all the companies participating in the supply chain.

What Can Be Done?

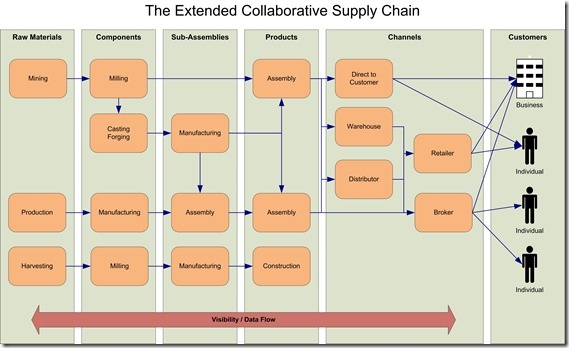

Let’s take another look at extended collaborative supply chains—like this:

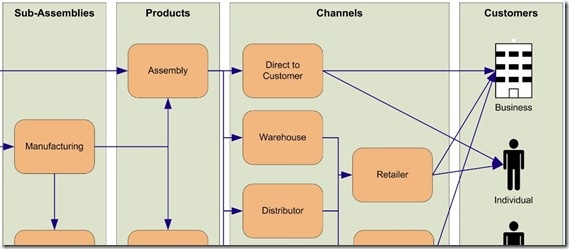

Now, let’s consider the players in just a smaller piece of this extended supply chain—something along these lines:

We have the following players:

- A manufacturer

- A final assembly operation

- A direct-sales firm

- A wholesale warehouse

- A distributor

- A retailer

Every one of these players is looking out for his or her own interests. Each participant in the supply chain is seeking to maximize its profits—or, at least, I hope it is.

How can we possibly bring meaningful collaboration out of this mess?

Cost-World Thinking Leads to a Zero-Sum Game

Whether firms who have achieved genuine, durable and agile supply chain collaboration use the terminology I am about to apply or not, I can say with better than 90 percent certainty that durable collaboration has not been erected on cost-world thinking!

If the final assembly operator is thinking that the way to make more money tomorrow than it is making today is by getting the manufacturer to reduce its prices (cut into its own margins), that thinking will only go a short distance before any hope of further collaboration dissolves. The same is true if the wholesaler or distributor are hoping to improve their profitability by getting the final assembler or the manufacture—or both—to cut costs and reduce their prices.

The assumption underlying such supply chain tactics is this:

If my company is going to make more money, then someone else upstream in my supply chain needs to find a way to make less money or cut their expenses while still offering better prices to my firm.

Essentially, the reasoning is that the supply chain is a zero-sum game (or so close to it that any differences from it are virtually indistinguishable).

Of course, those of you who have been through this already know where I’m going with this: durable and agile supply chain collaboration is, of necessity, built on the upside to be gained through collaboration.

Making the Move to Throughput Thinking

The cost world has its limits.

After all, it is possible to cut a firm’s cost of doing business to zero!

It’s call “going out of business.

And, if you’re a manager or executive in a small business trying to make in today’s world, you may be one who has felt the pressure of leading “big box” merchant strong-arming you to take less and less in profits while volumes increase to higher and higher levels. Now you’re making and selling more product than you ever thought possible and, yet, taking less to the bottom-line than you did before you bought into your first EDI contract!

I once had an executive in a distribution operation selling to major “big box” firms all across the U.S. tell me: “We can ship $20,000 worth of merchandise to [named company] and end up owing them $5,000 when all is said and done.”

Such experiences—and worse—are what drive many participants out of major supply chains.

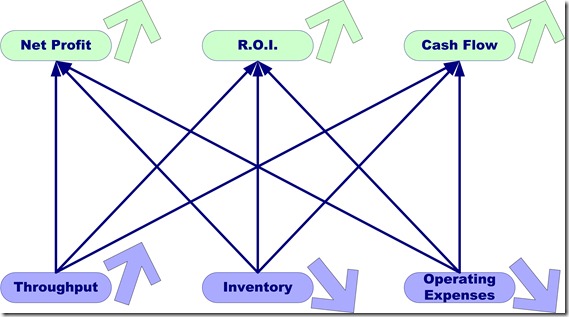

However, imagine a truly durable, truly flexible, truly agile supply chain that focused its collaborative efforts on increasing Throughput (i.e., the difference between revenues and truly variable costs) for every supply chain participant? Think where that might take those who labored for its success.

This Goes Way Beyond Sharing Data About Who Bought What Quantities Where!

Consider the following questions, as examples:

- What can the retailers—who interact on a day-to-day basis with the end-users—tell the manufacturer about what the consumer likes or doesn’t like about the products? Rapid and frequent feedback on this channel could lead to speedy improvements in product design and increased Throughput for the whole supply chain.

- What could the final assembly operator tell the manufacturer that might make the products more flexible and less burdensome on the supply chain at the same time? Perhaps the assembler could recommend concepts that could delay decision-making and lead to greater flexibility. This could lead to fewer out-of-stocks and fewer liquidations of overstocks at the same time.[1] The final assembly operator might also be able to suggest changes that would minimize the required variety of parts while still meeting all customer demands. This, too, would reduce supply chain inventories and liberate supply chain resources for that which is necessary to produce and ship to meet actual end-user demand.

- What feedback could a collaborative retailer or distributor provide to wholesalers or manufacturers about actual changes in market demand? These data could eliminate or dramatically reduce the bullwhip effect in the supply chain. This could liberate resources to manufacture or transport what customers are actually seeking to buy, rather than tying up resources manufacturing and transporting units of goods destined only to sit on pallets and, ultimately, liquidated at or near cost.

The Bottom Line is the Bottom Line

Ultimately, the goal of such collaboration—broad, extensive and extended supply chain collaboration—is mutually beneficial to all the supply chain participants. Unlike cost-cutting efforts, everyone benefits. There is no more zero-sum game.

The efforts described in the examples above should have the following mutually-beneficial effects:

- INCREASE Throughput

- REDUCE Inventories—along with the need for other capital investments

- DRIVE DOWN Operating Expenses—or, at a minimum, hold the line on operating expenses while allowing substantial growth in supply chain Throughput

The benefits, which should also spread across the entire supply chain, are

- INCREASES in net profits

- INCREASES in return-on-investment (ROI)

- INCREASES in cash-flow

Summary

I am convinced that truly collaborative, agile and durable supply chain collaboration is achievable when it is based on increasing Throughput and not driven by cost-world thinking.

[1] Hewlett-Packard made such a change some years ago whereby they made the power supplies for their printers modular and allowed “final assembly” to install the power supply hardware after the destination country was known. This lead to several billions of dollars in savings over a short period of time as zero products were produced where the power supplies were incompatible with the countries for which orders existed. More orders were able to fulfilled without delay and zero overstock existed for printers with “the wrong” power supply to fulfill open orders.

Building Lean Supply Chains with the Theory of Constraints: Mandyam Srinivasan: 9780071771214: Books Building Lean Supply Chains with the Theory of Constraints: Mandyam Srinivasan: 9780071771214: Books |

We would like to hear your thoughts on this topic. Please feel free to leave your comments here, or contact us directly.