Recently I visited a client’s office. I was told that this client really was focused and governed by the 80/20 rule (also known as the Pareto Principle).

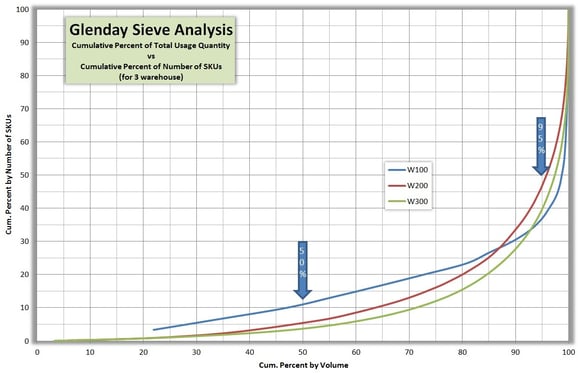

Unfortunately, I had some bad luck with my return flight and ended up with an extra night in a hotel room. So, I decided to run a Glenday Sieve analysis on the activity in this client’s primary warehouse (For more information on the Glenday Sieve, you can read my articles posted here and here for starters).

What I discovered was little short of astounding to me.

The 80/20 Rule as a Red Herring

Clearly, this analysis was preliminary and there is likely far more to be discovered and unraveled about what is actually going on. But here are a few numbers:

- The warehouse has 568,412 SKUs associated with it

- Of the more than half-a-million SKUs, only 223,446 (39.3 percent) ever had usage activity against them

This outcome alone likely indicates some combination of four possibilities:

- There may be a large number of SKUs that are associated with this warehouse that are drop-shipped and, therefore, are never consumed out of this warehouse directly

- There may be a large number of SKUs that were created as inventory master records, but never transacted against for one reason or another

- There may be a large number of obsolete SKUs in the warehouse from relatively “ancient” history

- The data in the warehouse’s records are just really screwed up

Anyway, here’s the rest of the analysis:

- Half of the unit volume moved through the warehouse is transacted against on 2,950 unique SKUs—that’s 1.3 percent of the 223,446 SKUs that actually had usage activity in the warehouse

- Fewer than one-third (32.8 percent) of the 223,446 SKUs account for 95 percent of the unit volume transacted in the warehouse

- The remaining five percent (5%) of warehouse activity is scattered across more than 150,000 SKUs, or 67.2 percent of SKUs (Note: This may be indicative of a large number of one-off sales transactions that involved cross-docking through the warehouse.)

Suffice it to say, the history of this warehouse is not governed by an 80/20 rule.

Rather, it is governed by a 99/1 rule!

Conclusion

In circumstances such as these (and certainly there is more to be learned about these unusual findings), policies, procedures, strategies and tactics need to be evolved around the precise nature of the supply chain activity. This supply chain cannot — and indeed, should not — be managed like any “normal” supply chain.

Furthermore, strategies, tactics and policies will need to cover the full range of corporate activity—from marketing to purchasing and replenishment to warehouse management and organization.

If I get a chance, I will try to give you “the rest of the story”—as Paul Harvey used to say—as soon as I know it.

In the meantime, please leave your comments and questions here.