Sometimes, it's inevitable that material ends up in a subcontract location, but it's not always needed there. In such instances, it's essential to know how to transfer the material to an internal location where it can be put to better use. This guide will take you step-by-step through the process of transferring the material from a subcontract location to an internal location so that you can get the most out of it.

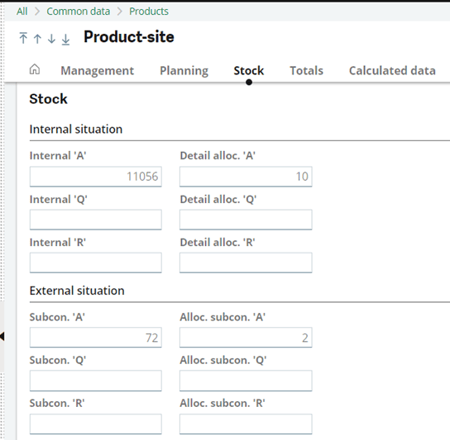

To provide a clearer understanding of the material transfer process, it's important to note that the Product-Site record used in this example displays the quantities of the item in the External situation section on the Stock page. This information is crucial as it indicates that the material is currently located in a subcontract location, which may not be the most optimal location for it. By transferring the material to an internal location, it can be utilized more efficiently, maximizing its potential and ultimately resulting in cost savings for the company.

Currently a quantity of 72 of this component “SUB1COMP” is in a subcontract location. (External situation: Subcon. A)

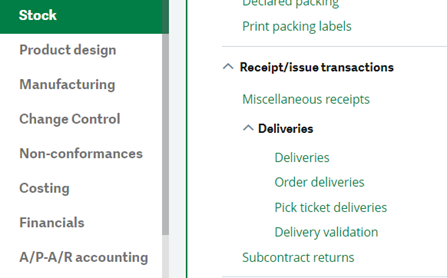

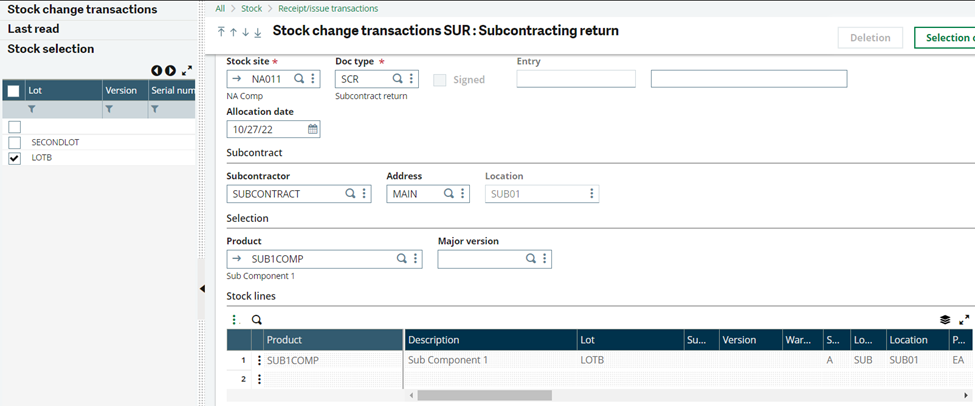

Go to Stock

Hold cursor over "Receipt/issue transactions"

Select "Subcontract returns"

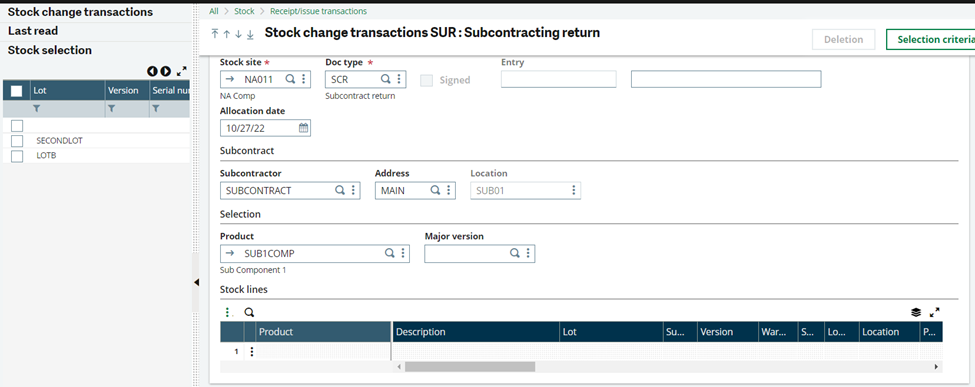

Enter the Site, Allocation date, Subcontractor, and Product

Click the ‘Stock Selection’ from the left list

Select the product from the Stock Selection left list. The grid will populate with the stock to transfer.

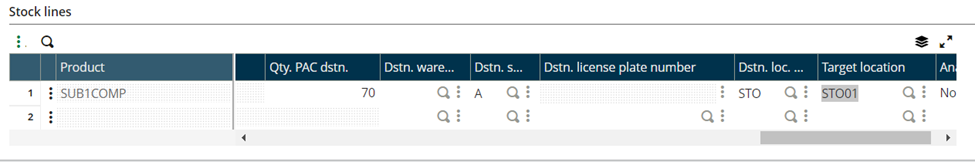

In the grid, scroll to the right until you see the "Dstn. Status", "Dstn.loc. type" and "Target location" fields. Populate these fields with the desired destination information for that material.

Click Create when finished.

Do you have other ideas for a helpful how-to tip? Let your RKL representative know!