Planned Order Not Coming up in Your Sage 500 MRP Plan

There are a few factors that may contribute to why a planned order is not coming up in your MRP plan. Issues may range from simple setup & configuration to more complex issues between quantities, dates, and replenishment trees. In this blog, I will discuss a few basic setups that may resolve your issues with expected items not showing up in your MRP plan.

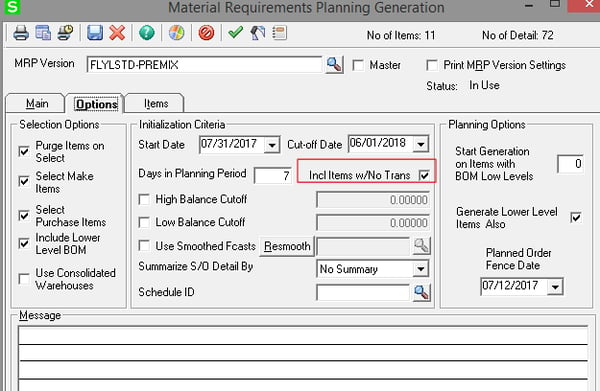

I want to mention a setting “must”. In your MRP Options window ALWAYS make sure to check the “Incl Items w/No Trans” button as noted below.

Next, we will divide items into two categories: Purchase Items and Make Items. The setup varies between the two and drives how replenishment will occur in the form of a Purchase Order or a Work Order.

Purchase Items

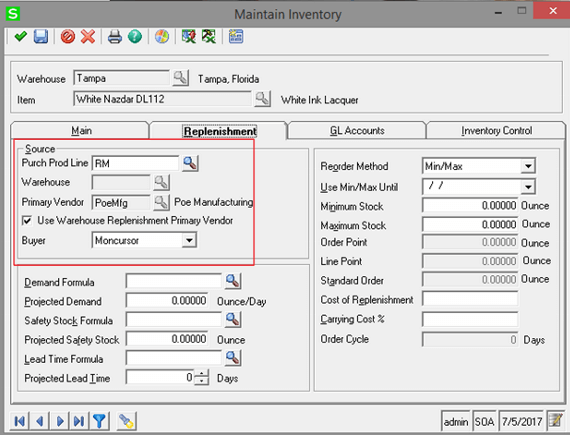

Maintain Inventory > Replenishment > Source area

You will need to have either a Purchase Product Line or a Warehouse defined for the source in Maintain Inventory. If the source of the item in the defined warehouse is a Vendor, enter the Purchase Product Line, Primary Vendor, and a Buyer. If you have more than one vendor for this item, you will be able to change the Vendor ID in the MRP plan before generating actual orders.

If the source of the item in the defined warehouse is another warehouse (meaning you transfer it from one warehouse to this one) enter the Warehouse ID instead of the Purchase Product Line.

Sage 500 Reorder Method

The reorder method for a purchased part will either be Min/Max, EOQ, Maximum Stock Level, or Manual. If your reorder method is set to Manual, the item will not appear on your MRP plan, so make sure you have that set accordingly.

If you have EOQ selected with various formulas for demand, safety stock and lead time, you will need to run your Inventory Replenishment (IR) steps prior to running MRP. This is a less common situation.

Make Items

In Maintain Inventory, the reorder method is required and is normally set to Min/Max. This will tell MRP to make quantities only based on actual sales demand.

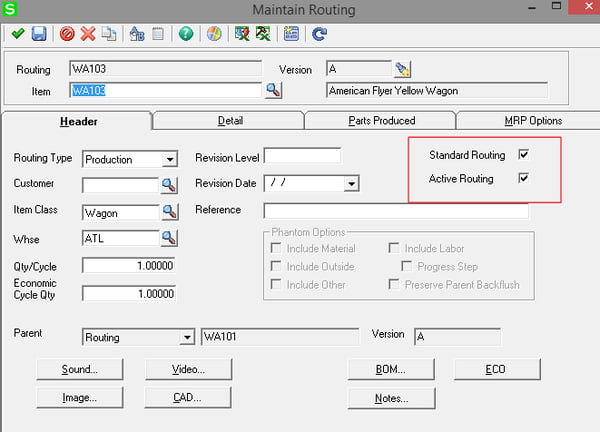

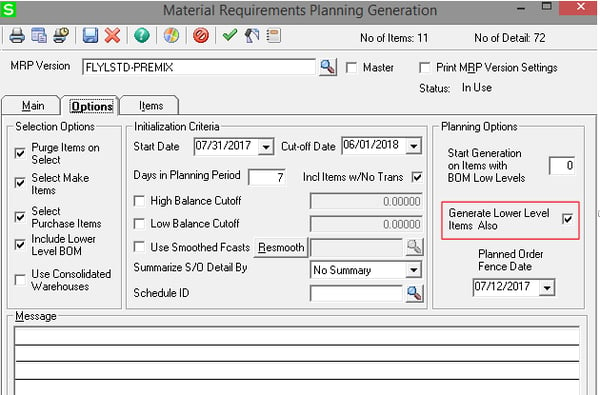

So how does MRP know whether the item is a Make or a Purchase? It’s based on whether there is an Active, Standard Routing for the item in each warehouse. Note that if you have a Routing where the Warehouse is not assigned (with the Standard/Active flags set), this is treated as the Active Standard Routing for all warehouses in which there is not a warehouse specific routing. As long as this exists for the item, it will always suggest a work order. When planning for a Make item, make sure the MRP Option to Generate Lower Level Items is also selected as shown:

Dealing with Sub-Assemblies

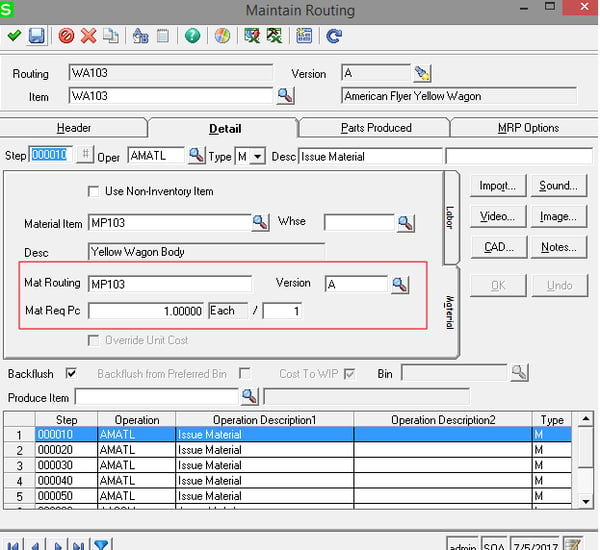

When a Bill of Materials includes intermediates or sub-assemblies, make sure that the routing detail line defines the Routing ID for the Sub-Assembly. This is how MRP links the lower levels and is able to plan work orders and/or purchase orders for the lower levels.

Other Considerations

-

- Make sure that there is a record in Set up Warehouse Replenishment because that is a required record for MRP to work even if it’s not being used as the default in Maintain Inventory.

- If you’ve checked that your setup is correct for your item and you’re still having trouble with the item not appearing in your plan, another possibility could be that it falls outside of the date ranges defined in MRP – especially if you have items with longer lead times. Stretch your start date earlier and your end date further.

- Control the date of generated orders by the fence date.