Are you disappointed with not being able to discover the answers to the following questions in your business or your supply chain?

- What needs to change so that we can make more money tomorrow than we are making today?

- What should the change look like?

- How can we effect this change?

Lisa Anderson recently wrote in "Strategy is easy; Execution distinguishes leaders":

Lisa Anderson recently wrote in "Strategy is easy; Execution distinguishes leaders":

"It is interesting to sit back and watch as companies spend millions of dollars on strategy formulation, just to achieve minimal results due to poor execution. Yet, the process repeats constantly – more money is dumped into strategy formulation, 3 ring binders, fancy Power Point slides, etc. On the other hand, I've found that strategy doesn't fail in formulation; it fails in execution.

"So, why not focus the resources on execution? In my experience, it might be due to the fact that execution isn't viewed as the exciting or 'high-level manager' activity. Give me a company that is excellent at execution with an 'ok' strategy anytime vs. a company with an awesome strategy with 'ok' execution…."

I would like to suggest that there are some other, perhaps additional, reasons so many companies spend so many of their valuable resources—time, energy, management attention, money—on strategy and still fail when it comes to achieving big—or even, consistent—success and improvement.

What holds companies and supply chains back from achieving more of their goals set by strategy?

A great many times, when we are faced with difficult—or, seemingly impossible—choices in our path toward fulfilling our strategy for success and ongoing improvement, we simply respond in self-defeating ways:

- We lower our expectations

- We compromise—attempting to please everyone by taking the worst of the best and the best of worse

- We avoid taking ownership of the issues at hand—finding someone else to blame (hopefully, someone outside our company)

- We find ourselves halting between two opinions—we oscillate between taking first this action, then that action, because both options have some negative consequences

- We simply give up and start ignoring problems that we think we can't do anything about

Taking any of these approaches does not lead to success or ongoing improvement.

Yet, a great many executives and managers in businesses of all sizes, in all sorts of industries, do just that. In fact, if you are honest, chances are my readers have had first-hand experience with taking one or more of these no progress responses to challenges they have faced in the past.

There is an art—even, a science—to really effective problem-solving

Eliyahu Goldratt once wrote: "We grossly underestimate our intuition. Intuitively we do know the real problems, we even know the solutions. What is unfortunately not emphasized enough, is the vast importance of verbalizing our own intuition. As long as we will not verbalize our intuition, as long as we do not learn to cast it clearly into words, not only will we be unable to convince others, we will not even be able to convince ourselves of what we already know to be right. If we don't bother to verbalize our intuition, we ourselves will do the opposite of what we believe in. We will 'just play a lot of games with numbers and words.'" – Theory of Constraints, (Great Barrington, MA: North River Press, 1990), p.3.

The key to effective problem-solving is verbalizing our intuitive knowledge and reasoning.

Doing this in prose has little effectiveness, however. It's too hard to digest. It's too difficult to rewrite. It's too difficult to visualize the cause-and-effect flow of our reasonings about the issues and challenges we face.

That is precisely why Goldratt came up with the Thinking Processes (Theory of Constraints).

Compare these two methods of expressing the same thoughts:

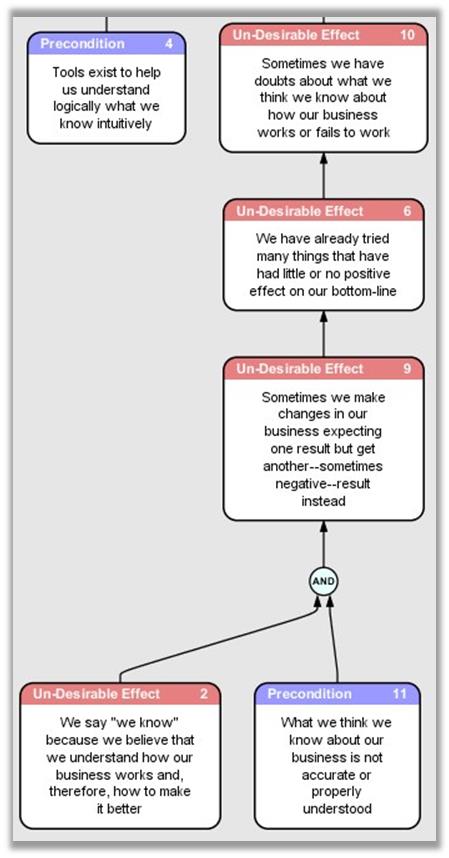

Method 1: Prose – If we say, "we know" because we believe that we understand how our business works and, therefore, how to make it better and what we think we know about our business is not accurate or properly understood, then sometimes we make changes in our business expecting one result but get another—sometimes negative—result instead. And, if that is true, then that would explain why we have already tried many things that have had little or no positive effect on our bottom-line. Hence, we now sometimes have doubts about what we think we know about how our business works or fails to work.

Method 1: Prose – If we say, "we know" because we believe that we understand how our business works and, therefore, how to make it better and what we think we know about our business is not accurate or properly understood, then sometimes we make changes in our business expecting one result but get another—sometimes negative—result instead. And, if that is true, then that would explain why we have already tried many things that have had little or no positive effect on our bottom-line. Hence, we now sometimes have doubts about what we think we know about how our business works or fails to work.

Method 2: Logic Diagram – Now, compare reading and comprehending the paragraph above to reading the accompanying diagram from the bottom to the top using IF…THEN statements.

Consider, also, which method of "verbalized intuition" would be easiest to revise—perhaps, multiple times—and be clear to the new reader with each revision.

My experience tells me that the Current Reality Tree (CRT) excerpt in the accompanying diagram gets the most votes.

Articulating and understanding our Un-Desirable Effects (UDEs)

Many organizations try to improve through "business process re-engineering" (BPR). I have been to organizations that, as Lisa Anderson stated above, spent tens of thousands of dollars and managed to accumulate several three-inch and five-inch thick three-ring binders to describe each and every process carried out within their enterprises.

Unfortunately, those kinds of flow-charts and prose generally do not capture where the real challenges to ongoing improvement lie.

Our experience tells us that the biggest hindrances to a process of ongoing improvement (POOGI) in most organizations and supply chains are not found in the processes themselves—or even the automation applied to those processes. The biggest hindrances are

- Policies – both written and unwritten

- Training – how employees are trained (are they trained "to think", of just "to do")

- Metrics – how are employees, departments, managers and executives measured

The diagram of the CRT excerpt is a "flow-chart" of sorts. But it is not a flow-chart of work. It is a flow-chart of the underlying "thinking," assumptions, policies and the effects of training and metrics that affect outcomes all across the organization or supply chain.

This kind of approach helps uncover the real issues that are keeping a company from making more money tomorrow than they are making today.

Resolving conflicts and inventing solutions

The Thinking Processes provide logic-based tools to help organizations

- Visualize and resolve conflicts

- Surface and validate or invalidate underlying assumptions

- Resolve interpersonal or interdepartmental conflicts

- Empower participants to visualize and innovate

- Invent real and effective solutions

- Manage the organization upwards – toward ongoing improvement

Execution is everything

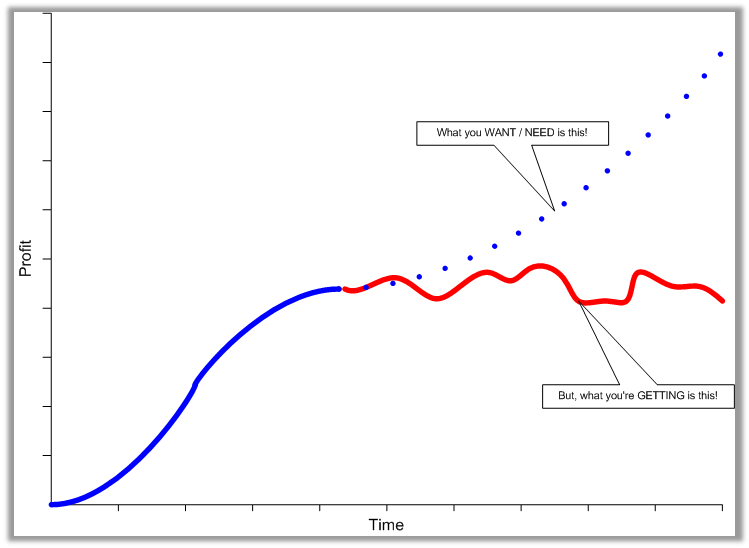

As Lisa Anderson so appropriately pointed out, the failure of organizations to actually achieve real improvement—a durable competitive advantage—is almost always rooted in execution failures, not in strategy failures. An company may fail to create a strategy. But, if they do create a strategy, I am doubtful that many corporate or supply chain strategies are focused on "being a fair-to-middling company making a minimum of profit and eeking by year after year." Nevertheless, that is precisely where a great many companies find themselves—year after year.

Linking strategies to effective tactics

Successful execution is derived from the ability to link effective tactics directly to the strategies that have been developed. The Thinking Processes provide a step-by-step method to build effective tactics to take a firm and, perhaps, its whole supply chain, from where it is today—its current reality—to where it wants to be (as indicated by its strategies).

Don't stop with strategizing and then feel like your vision can never be achieved because you feel trapped in your "current reality." There is help and there are tools available.

We would be delighted to hear what you have to say on this topic. Please leave your comments below.

[jbox color="gray"]

Related Articles:

Increase Profits with a Process of Ongoing Improvement

The Key to Changing the Way We Think

Creating Sustainable Growth

[/jbox]