One of the biggest problems in manufacturing is being able to schedule work orders in an efficient manner to reduce costs, prevent bottlenecks, prioritize work orders and track delayed or late work orders. LYNQ Solution Capabilities allows users in Sage X3 to do all those and more. LYNQ is a manufacturing execution system (MES) for small to midsize manufacturers that want to plan, track, automate, analyze and optimize their manufacturing process to increase efficiency, productivity and profitability.

In this blog, we'll take you through a brief overview of the functionality and interface of LYNQ and it's integration to Sage X3.

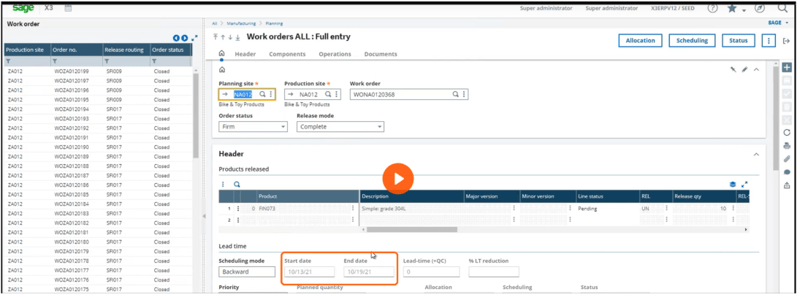

LYNQ functionality and user interface

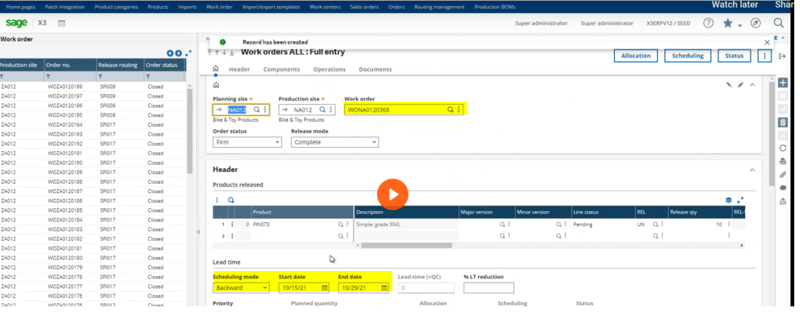

We have a work order created in Sage X3 with the Scheduling mode set to "Backward" and a set start and end date.

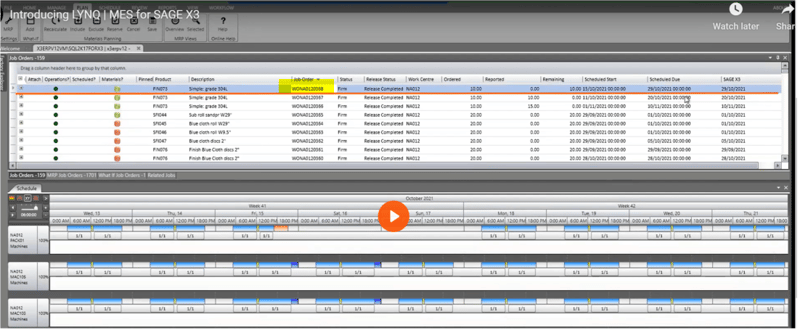

Once created and saved, through the X3-LYNQ integration and setup, the Work Order will appear in the Visual APS Task Panel.

The X3-LYNQ integration provides several benefits for business already running or considering X3 as an ERP solution:

- Real-time, bi-directional integration between the X3 and LYNQ system

- Fully configured, plug-and-play connector

- Technology leverages Sage X3 web services APIs for highest standards of performance, data integrity and security.

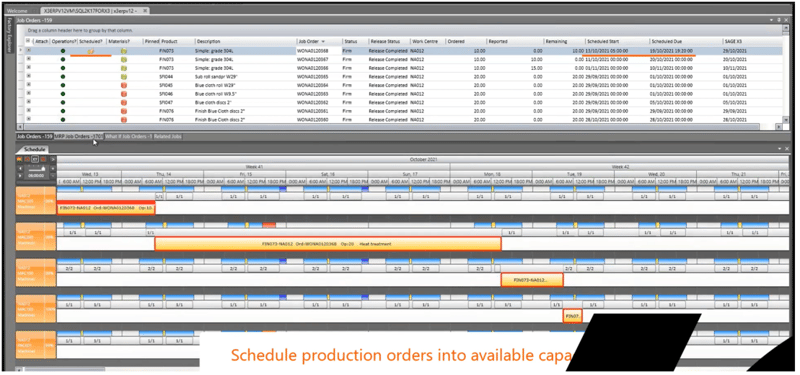

From the LYNQ Visual APS Task Panel we can auto-schedule all the work orders, or we can individually auto-schedule the work order, as we did below. (A drag and drop option is also available to schedule the work orders as well as move work orders on the planning board.) The work order now appears on the graphical planning board with a yellow thumbs up meaning it is scheduled on the planning board and represented by the operations in yellow. The start and end date are updated based on the automatic scheduling.

LYNQ’s scheduling solution adds real value in several ways:

- Provides advanced finite capacity-based planning and scheduling while minimizing downtime.

- Allows businesses to produce and deliver goods to customers faster and in the most cost effective way.

- Factors in constraints around machines, tooling, personnel and inventory to make best use of materials and resources.

We can Save and Publish back to X3 and see that the work order is updated with new start and end dates.

Production planning and scheduling between X3 and LYNQ can be utilized for both process and discrete manufacturing industries. Scheduling rules originate from Sage X3 routing and operation settings that have been optimized for scheduling.

Whether you're in the Automotive, Chemical, Food and Beverage, Life Sciences, Metal Fabrication, Oil and Gas, Plastics or Textile industry, we can help your business grow and run more efficiently. Contact us for more information about the integration between Sage X3 and LYNQ!