The true asset value of your inventory depends upon a large array of factors.

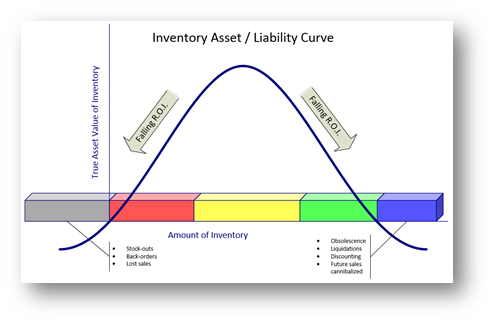

However, as Smith and Smith properly assessed in their excellent book Demand Driven Performance, the factors that make inventory valuable can be summed up in general way using the accompanying Inventory Asset / Liability Curve (figure).

The Cost of Too Much Inventory

When you have too much inventory, return on investment (ROI) begins to decline for any of several reasons including:

- Write-offs due to obsolescence tend to increase

- Increased discounts may be offered to "move" the product and, as a result, profit margins are reduced

- Liquidations may be required to unload inventory that is nearing obsolescence

- Liquidations of current models tend to cannibalize future sales, also reducing profits in the future

- The longer inventory is held, the more likely it is to suffer damage, or become shop-worn and require additional discounting or even be written-off

- Carrying costs increase

- Larger inventories may require additional capital investment in the form of more warehouse space, racking or shelving, and handling equipment

Unfortunately, the value of the inventory (an accounting asset) is very visible and may even be deemed positive in some respects. The costs, however, tend to be diffused and harder to recognize. These costs are no less real merely because they are diffused instead of concentrated and easily seen.

The Cost of Too Little Inventory

When you have too little inventory revenues can fall and operating expenses increase dramatically:

- Expediting expenses may increase dramatically as overtime and additional personnel resources are diverted to firefighting

- Excess freight costs—the extra you pay for expedited shipping—my explode higher

- Backorders mean you are more likely to have to make second and third shipments at your expense

- Stock-out may lead to lost sales

- More stock-outs may lead to lost customers

- Lost sales lead to increased sales and marketing expenses to make up for sales and customers lost

Both Tails Mean Reduced R.O.I.

Just as the accompanying figure clearly shows, both ends of the curve—both tails—mean falling ROI for your company or your supply chain.

Becoming truly demand-driven (this is not the same as make-to-order) in both planning and execution has clearly demonstrated its effectiveness at squeezing your inventory effectively into its most profitable range.

It Cannot Be Done by Finance

Reshaping your inventory cannot be done at the gross level. The only way to do this effectively is to determine where your red zone, yellow zone and green zone is for each SKU in each location. As Lora Cecere cogently observed in her article Seven Misconceptions on Managing Inventory in a Market-Driven World, "A frequent mistake made in the management of inventory in the extended supply chain is a blanket reduction—a corporate mandate to reduce inventory—without rationalizing the requirements for inventory in the value chain. Inventory should never be managed to a financial target."

We have the tools to help companies and supply chain managers move steadily toward maximizing the ROI they get from every dollar invested in their inventories.

Executives and managers just need to begin giving up on their misconceptions in order to take advantage of these new, proven-effective demand-driven approaches to improvement.

[feature_box_creator style="1" width="" top_margin="" bottom_margin="" top_padding="" right_padding="" bottom_padding="" left_padding="" alignment="center" bg_color="" bg_color_end="" border_color="" border_weight="" border_radius="" border_style="" ]

Event: RKL's 2016 Manufacturing & Distribution Forum: The NEW Industrial Revolution

When: Thursday, September 22nd | 8:30am to 3pm est | Reading, PA

Forum Registration

[/feature_box_creator]