Here is letter to a typical client (with some redactions). See if you find yourself in the same case as they find themselves.

*******************

Gentlemen:

Thank you for today's teleconference. We trust you found it helpful. It was certainly our pleasure to speak with you on the matters with which you are concerned.

We believe that there are really five essential steps to effective inventory and supply chain management in today's highly volatile and competitive business environment. Those steps are these:

- Strategic Inventory Positioning – Failure to determine where in your supply chain inventory should be positioned is a huge source of waste in most supply chains. Any investment in stock for a given SKU-location is strategic if—and only if—it satisfies the following three requirements: 1) it absorbs variability in supply and demand, 2) it decouples lead times, and 3) it provides real ROI—that is, ROI that can be computed!

- Buffer (stock) Profiles and Levels – The establishment of stock profiles and initial buffer (stock) levels.

- Dynamic Buffer Management – The creation of tools and methods to automate the dynamic management of stock buffers. In my opinion, dynamic management should be done daily, and therefore, must be automated. Contrary to what one might initially think, making daily dynamic changes to the factors governing buffer levels actually reduces

system nervousness. The reason this is true is that the daily adjustments are small and incremental—most often a fraction of unit in ADU (Average Daily Usage)—which leads to small incremental changes in replenishment orders. Large-scale monthly changes lead to large-scale changes in replenishment orders, as well. This simply aggravates the bullwhip effect up and down the supply chain. - Demand-Drive Planning – Planning must be based on the maintenance of FLOW. All of the benefits in a supply chain accrue from the FLOW of relevant information and relevant materials. Too many supply chain managers are drowning in data while lacking the ability to sort out the relevant information from the background noise.

- Visible and Collaborative Execution – The creation of a high-visibility and collaborative environment for management of the supply chain is essential for ongoing improvement. This should include 1) the creation and training of a cross-functional management team; 2) the development of new and effective KPIs for measuring inventory and supply chain performance in terms of FLOW; and 3) the creation of an effective POOGI (process of on-going improvement) to prevent stagnation at any level.

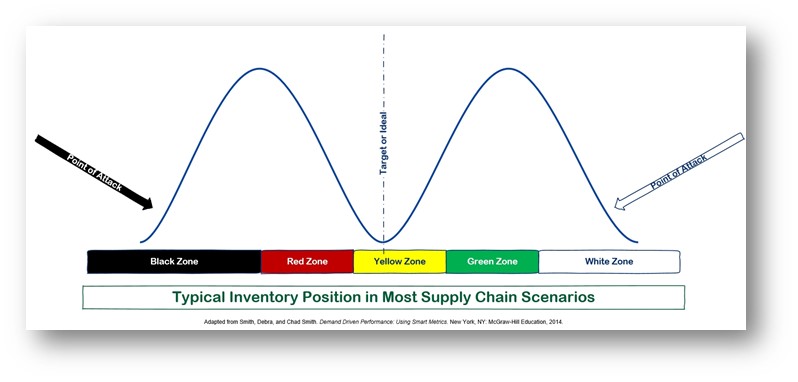

When we start working with most of our clients, their inventory looks like this:

They typically have very few SKU-locations (SKULs) in their "ideal" or "target" inventory range. Instead, they have a large number of SKULs with too much inventory (the right-hand part of the figure above), and a large number of SKULs with too little inventory (the left-hand portion of the figure).

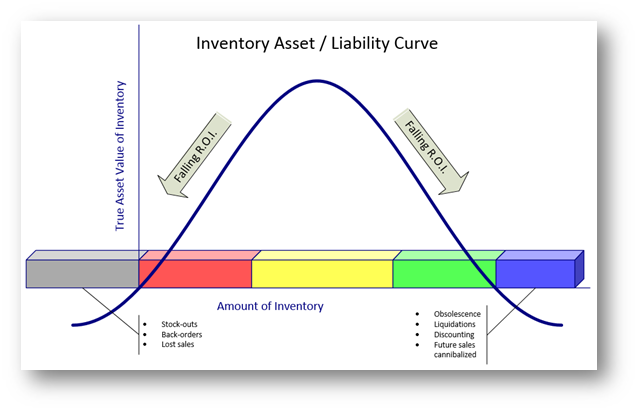

What they want—and need—is inventory that looks like the figure at the right. All of the ROI to be found in carrying inventory is found in having a supply chain that supports FLOW. Inventory that is missing (out-of-stocks) and inventory that is sitting still (excesses) only diminish ROI.

The reason most companies' inventory is in a bi-modal distribution is because none of the five essential steps are in place.

- Inventory has never been strategically positioned

- Buffer (stock) levels have never been calculated by rules based on the maintenance of FLOW

- Buffer (stock) management is not dynamic

- They have not implemented demand-driven planning tactics; nor the ability to sort out relevant from irrelevant information from their systems

- The do not have—or know how to create and train—an effective collaborative cross-functional team for supply chain management either within their organization or in their extended supply chain

Here Is the Good News!

Sage Inventory Advisor (SIA) essentially does steps 1, 2 and 3 for you—automatically.

While SIA does not take the demand-driven approach to calculating ROI for each SKUL, it does apply statistical methods that are well beyond the capabilities of most small to mid-sized business enterprises in order to begin reshaping your present bi-modal inventory.

SIA does automatically determine buffer (stock) profiles (step 2) beginning day-one, and hones each buffer profile day-by-day as new relevant information becomes available to it.

Therefore, SAI is also—day-by-day—undertaking the process of dynamic buffer management, making incremental adjustments to your buffers. This leads, over time, to the reshaping of your inventory from bi-modal toward increasing ROI and an inventory that looks more like the second figure above.

Other Alternatives

In our telephone conversation, we talked about other alternatives. Here are some comments on these alternatives:

- Sage 500 MRP with Demand Smoothing – Traditional MRP is a powerful tool. However, one must remember that traditional MRP—whether found in [Product name] or [Product name]; whether purchased for $10,000 or $10,000,000—is all predicated on logic that emerged in the 1940's and 1950's; was developed into software in the 60's, 70's and 80's for the most part; and has not changed significantly since. It was designed and built for the world and competitive environment that is much different from today's world.Traditional MRP is designed to manage all inventory to zero plus safety stock. If you do not recognize its limitations, you are likely to get burned. This is why worldwide companies of all sizes, running hugely expensive MRP implementations, are much more likely than not to supplement their MRP data—and make final replenishment planning decisions—based on Microsoft Excel™ spreadsheets and in-house developed applications, rather than on the raw data coming out of MRP.

- Third-party demand planning, forecasting and smoothing products – There are many third-party demand planning, forecasting and forecast smoothing products that could be considered. Remember, however, that in the absence of sound underlying data (e.g., lead times, demand variability, supply variability, average daily usage) you are likely to get numbers, believe the numbers, and discover that the numbers are wrong in the end.All forecasts are wrong! The only thing we don't know when we reduce a forecast to a single value is how much it is wrong, and in which direction. Therefore, as a Certified Demand Driven Planner, I am a strong advocate of using forecasts for large-scale decisions (e.g., capacity planning) only. Short-term decisions about inventory buffer sizing and replenishment actions should be determined by actual demand in the system (i.e., FLOW), relying upon the buffer to do its job (absorbing supply and demand variability).

- Sage Intelligence – Sage Intelligence is certainly a capable tool that can be used in a number of ways, including the creation of dashboards, alerts and notifications. This is really a function of steps 4 and 5 above. Needless to say, if steps 1, 2 and 3 are not carried out (or poorly executed), whatever tools you choose to use in steps 4 and 5 will merely supply you with bad data and, perhaps, irrelevant data.Therefore, before deciding what tools you might use in steps 4 and 5, one must lay a sound foundation in steps 1, 2 and 3.

- Other Options – If you were to look for a truly demand-driven solution, one could hardly go wrong by taking a serious look at Replenishment+®, a product from Demand Drive Technologies. It is also quite possible to implement many demand-driven principles within the context of [given Product name], but this would require some adaptation, along with some Customizer work, and the development of some SQL components and (possibly) a handful of source code changes. We have already done some prototyping in this area.

Next Steps

We are happy to coordinate your review of a demonstration of any of the products we have identified above, and supply you with further information, as well.

Additionally, we are prepared to supply you with training and consulting to fulfill the requirements of steps 4 and 5 listed above. Remember, when we say 5 essential steps, the word "essential" means just what you think it means. Companies may skip any of these steps, but when they do, they give up ROI and improvement opportunities.

Generally, the result of skipping any of these 5 essential steps is precisely what you have already been experiencing: bi-modal inventories and costly fire-fighting and expediting. All of these other actions are non-value-add and tend only to increase operating expenses and reduce profits.

We are here as your partner in success. Let us know how we can help.

Please do not hesitate to contact us with your further questions or concerns.

Very truly yours,

*******************

![]()

Does your case match theirs?

What steps are you taking to end the ongoing battles of fire-fighting and expediting? We would like to hear from you.

[si-contact-form form='1']