Who says you can't win 'em all?

Most of the companies with which we work would really like to "win 'em all." They'd like to have the lowest costs, the best sales, lowest operating expenses and highest profits in their league.

The problem is that no matter how much they try; no matter how many metrics and incentives they put in place; they just can't seem to achieve the results they are after.

They've got sourcing and production people pounding away at reducing costs and improving efficiencies. They have given them powerful incentives to do so.

They also saw to it that their sales and marketing folks are incented to deliver the kinds of sales they need to be profitable.

And, of course, the whole C-suite keeps accounting, finance, and the whole management team focused on holding the line on operating expenses and improving profits.

But, maybe the whole scenario described above is the problem!!!

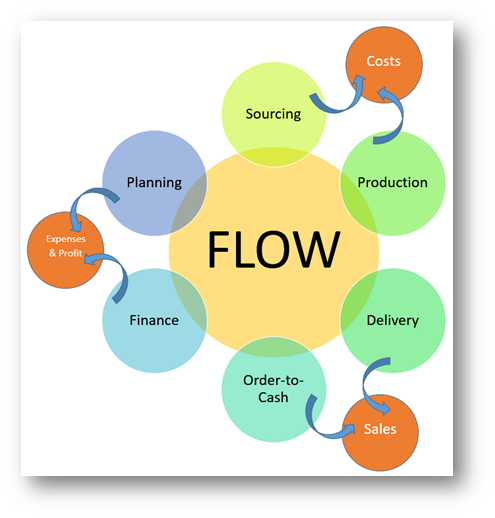

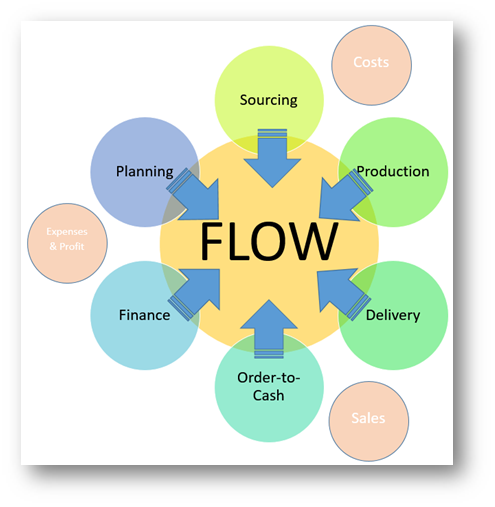

The purpose is FLOW

When manufacturing and distribution organizations are conceptualized—when the idea evolves into a business concept—the underlying purpose is understood to be FLOW.

That is to say, products are…

- Mined or grown

- Manufactured or assembled

- Shipped or warehoused… all of the purpose of FLOWing them to customers!

Interestingly, in the early entrepreneurial days of the enterprise, the focus is almost entirely on FLOW.

It is only as the enterprise grows and the bureaucracy of departments, divisions, and functions evolve that the FOCUS becomes something else.

As a result, soon the wonderful unity of the organization becomes one of politics and finger-pointing.

Meetings end up sounding like this:

- Sourcing – "The reason we can't reduce our costs any more than we have is that finance doesn't want us to buy any more inventory, so we can buy in the lot-sizes we'd really like to in order to get a better price."

- Production – "We could have better efficiencies, but sales keep coming down demanding that we break our set-ups in order to get some order out for an important customer. Oh! And don't forget the crazy mess at end-of-quarter when limits on overtime go out the window and we're all driven to 'get those orders shipped before the end of the month no matter what!'"

Shipping – "We can't ship what we don't have. If Production could be making what we need instead of what's on their schedule, we could ship more orders on-time and complete."

Shipping – "We can't ship what we don't have. If Production could be making what we need instead of what's on their schedule, we could ship more orders on-time and complete."- Sales & Marketing - "Our job is to get sales. But every time production and the warehouse let us down by not having what the customer wants when the customer wants it, we have to either cut prices or lose the sales. It's a mess."

- Finance – "We've got $28 million tied up in inventory and work-in-process now! How can we even be in the situation of not having what our customers want on any given day of the week?"

It's "a house divided against itself." But it is altogether too common. You have probably lived this—and maybe are living it today.

What happened to the entrepreneurial focus on FLOW?

You really need to get back to this focus on FLOW.

Interestingly, the evidence is in that when the whole supply chain is focused on FLOW in an effective way, then…

- Costs go down

- Operating expenses are held to a minimum

- Sales go up (because more customers are being satisfied), and

- Profits rise

It's sort of like driving your car.

Stop-and-go traffic reduces your mileage. Everything is less efficient.

But, when you get out on the highway, stops and slow-downs are reduced or eliminated, and speed is increased, your car automatically delivers more miles-per-gallon. Efficiency increases without a focus on efficiency.

In your business and supply chain, viewed as a system, system efficiency can be measured as

System Efficiency = Throughput / Operating Expenses

or

System Efficiency = (Revenues – Truly Variable Costs) / Operating Expenses