We are continuing our discussion stemming from an insightful white paper published by The Boston Consulting Group, BCG sets forth some very cogent points that should be—indeed, must be—considered by any supply chain managers hoping to increase their success over the coming years.

We are continuing our discussion stemming from an insightful white paper published by The Boston Consulting Group, BCG sets forth some very cogent points that should be—indeed, must be—considered by any supply chain managers hoping to increase their success over the coming years.

Realigning Performance Metrics and Incentive Plans

The BCG report suggests that “[t]he ultimate goal of a DDSC (demand-driven supply chain) is to ensure the best service at the lowest cost.” Of course, in a general sense, this should be the goal of every supply chain. It is, however, worth noting that successful supply chains are capable of delivering more of that goal than traditional supply chains.

More importantly, I believe that even this statement is far to general. If the for-profit organization is honest with itself, then the real goal of the supply chain is to increase Throughput while holding the line on operating expenses (or even reducing them) at the lowest possible increase in investment (which includes inventories). Subscribing and working diligently toward this goal maximizes ROI (return on investment).

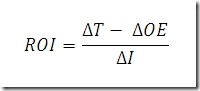

This goal may be simply stated in the formula shown here:

The formula may be read as: “ROI = (the change in Throughput less the change in operating expenses) divided by the change in investment.” Throughput, here, carries a very specific accounting definition being revenues less truly variable costs (TVCs).

The authors of the BCG white paper also correctly assess that movement toward any goal is accomplished most effectively when “the performance targets and incentives of all supply-chain players must be aligned so that everyone is marching in the same direction.”

If some supply-chain participants remain entrenched in cost-world thinking, they will invariably end up being at odds with those who have been captured by Throughput thinking. The upside for improving Throughput has no theoretical limits and, properly effected, virtually no down side. On the other hand, there are very finite limits to cost-cutting and a very definite down side. In fact, many formerly very successful companies who saw themselves as “cost-cutters” in years gone by are simply no longer in business. Even Wal-Mart's demand-driven supply chain is focused primarily on assuring increasing Throughput, not on cutting costs, to produce increasing profits.

DDSCs are successful and achieve rewards for all the supply chain participants because everyone in the supply chain wins when Throughput is increasing. Only one—or a very few—can win when the focus is on cost-cutting and the downward spiral of cost-world thinking.

Cogently Managing the Trade-offs Between Cost and Service

In this area, I may have some disagreement with the BCG authors of the report we are discussing. If I understand what the authors are saying in regard to this topic, it would seem that they are suggesting that “complex analytics” are required to calculate the cost-benefit results of various options in the DDSC.

I simply do not believe that this is true.

If there are unmitigated risks to movement toward the development of a demand-driven supply chain, those risks are found primarily in taking half-measures or attempting to “do” demand-driven without understanding the cultural shifts that are necessary to making a DDSC work effectively for all the trading partners.

In my opinion, it is a mistake, for example, to attempt to reduce inventories in the supply chain without taking what should be these parallel and essential steps:

- Increasing the agility of the supply chain

- Reducing the replenishment cycle time

- Buffering against “Murphy” with capacity and flexibility

- Reducing the size of production and transfer batches wherever possible

- Increasing, inasmuch as possible, visibility of actual end-user demand all across the supply chain

Effecting Change in the Corporate Culture

“To work, DDSCs require major organizational and behavioral changes,” the authors of the BCG report opine, and I could not agree more.

Sadly, it is for this very reason that too many organizations and their supply chains will forego the generally dramatic benefits and growing profits to be delivered by DDSCs.

Too many small business firms are bound by written and unwritten policies and procedures that have become organically entrenched in the very fiber of the enterprise. No one is willing to challenge these. The excuse—even if unspoken—is, “We’ve always done it this way,” or “It’s never been a problem in the past, so why should we change anything now?”

It is also on this very point that having someone from outside the company—outside “the forest” and away from “the trees”—who can bring tools to bear in assisting the executives and managers in unlocking “tribal knowledge,” can be exceedingly valuable.

Contrary to popular opinion: people do not hate change.

What people “hate”—what people militate against and undermine—is change for which they are not yet convinced there is an enduring benefit.

Unlocking tribal knowledge and helping executives and managers discover their own reality and design their own solutions brings all the negatives to an end.

No one fights against the solution they have designed.

This is the real corporate culture change that leads to a process of ongoing improvement (POOGI).

We are interested in what you have to say. Please leave your comments here, or feel free to contact us directly, if you prefer. We look forward to hearing from you soon.