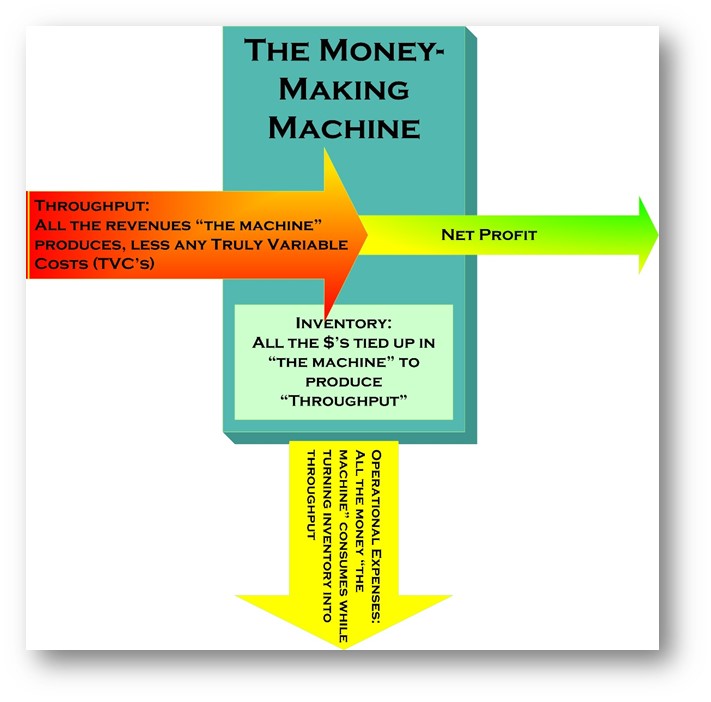

All kinds of things have been written about ERP (enterprise resource planning) implementation failures over the past 20 or more years. Most of these articles have focused on failures to deliver a acceptably performing system on time, within the prescribed budget, or of a quality that support ongoing business requirements. And, while all of those failures are significant, what troubles me more (if you have read my writings for long) is knowing how many "successful" ERP implementations lead to no significant improvement in the enterprise's profit performance.

Our goal is to do everything within my small power to change that for the clients with whom we work. For me, personally, if a client is not more profitable and seeing rapid ROI (return on investment) from its ERP deployment, then the implementation was not successful regardless of its on-time, on-budget status.

Why can I say that?

Because if a company is going to spend $75,000 or $150,000 or $500,000 on any kind of "investment," then it seems like they should expect a return on that investment. If they are getting no effective return on investment, then it was not an "investment," it was an expense—plain and simple. All else being equal, if after-tax profits were X percent before the implementation and they remain X percent after the implementation, then there is no effective ROI flowing from the "investment."

An article by Daniel Erickson, published on the Web at Manufacturing Business Technology* listed some of the reasons ERP "implementations go all wrong."

The first that Erickson lists is "Lack of buy-in." In describing this symptom, he says this:

The Captain's chair should be occupied during this foray into the relative unknown. An engaged CEO will inspire top managers and decision makers to take up command positions "on the bridge" of the enterprise. Create a company-wide awareness of this major undertaking, with a call for "all hands on deck." Each employee should know the destination (full ERP implementation) and understand the timeline for arrival.

Now, I don't know about you, but for me, this paragraph does not speak of "buy-in." For me, this paragraph is all about "command and control." "Each employee should know the destination…and understand the timeline…."

Now, "buy-in," for me, would sound something like this:

The executive sponsor of the ERP technology project has engaged a cross-function and vertically-integrated team of leaders from across the enterprise to help determine what needs to change in order to help the company make more money tomorrow than they are making today. Using guided processes that help the team clearly visualize and logically analyze what makes the whole enterprise work—or fail to work—the team has reached unanimity, not only on what needs to change, but also on what the change should look like. From this position, and using logical tools that help them clearly articulate these requirements, they have also been able to get the entire organization—all the way up to the production floor—excited about creating and activating these new solutions. Using these same "thinking processes" (a set of logic-based visual tools and exercises), they have also been able to find the appropriate technologies and locate engaged software vendors and VARs that equally excited about helping the enterprise create a new future and achieve rapid ROI for their planned investment.

What do you think "buy-in" should sound like or look like? Let us know by leaving your comments here.

* Erickson, Daniel. "10 Often Forgotten ERP Implementation Faux Pas." Manufacturing Business Technology. March 10, 2015. Accessed March 11, 2015. http://www.mbtmag.com/articles/2015/03/10-often-forgotten-erp-implementation-faux-pas.

[feature_box style="2" only_advanced="There are no title options for the choosen style" alignment="center"]

Learn More ...

Learn More ...

Grab a copy of The 8 Sins of ERP Project Failure.

This free guide provides insights about how to avoid common mistakes and ensure a successful ERP implementation.

Download Free Guide [/feature_box]