If your enterprise is designed to make money through the manufacturing or distribution of goods, then there are really only two—that's right! Two—metrics that truly measure the performance of your supply chain:

- Return on investment (ROI)

- Due-date performance (customer service levels).

Every other metric or KPI employed by the organization should be directed at simultaneously driving these two system-wide metrics higher, in a process of ongoing improvement (POOGI). There should be no "trade-offs" here—as are so frequently claimed by some. In the long-run, there is no need to sacrifice ROI for due-dates, or vice-versa.

So, whose job is supply chain management (SCM) anyway? Is it the job of your designated "Supply Chain Manager"?

Supply Chain Management is Everyone's Job

Sadly, in too many organizations, the title of "supply chain manager" is just that—a title. This is the employee frequently caught in the middle of battles between Sales and Marketing (who want the system to favor FLOW over costs (unless the rising costs will affect their personal incomes via commissions) and Finance (who frequently see their job as "controlling costs") and Operations (who are frequently measured by Finance based on "cost performance").

In such cases, the supply chain manager's job become little more than making sometimes vain attempts to satisfy the "biggest bully" at the present time. Sometimes the biggest bully is Sales and Marketing, pushing operations to get things built, bought and out-the-door. Not infrequently, Sales and Marketing may have an ally in Finance—especially near quarter-end or year-end. At times such as these it's "Damn the costs! Just get the stuff to our customers so we can get it invoiced!"

Under these circumstances, inventory levels may skyrocket, excess freight costs may explode, and expenditures on overtime may double or triple, but—for the moment, anyway—FLOW is king! Everything is sacrificed as such times to FLOW—including the willingness to "break" set-ups and reduce batch sizes.

However, once this quarter-end or year-end cycle has run its course, the supply chain manager may be bullied with nearly equal vehemence to "slash needless inventories" and "make sure our manufacturing costs don't get out-of-hand." "No more overtime," comes the call from Finance; and "increase batch sizes to improve our efficiency metrics," Operations is commanded.

The all too frequently occurring picture just painted in the paragraphs above happens more often than most companies would like to admit. Such management oscillation is very damaging to morale and leads to a process of ongoing firefighting instead of ongoing improvement.

That is "supply chain management as everyone's job" at its worst!

There is a Better Way

We are 100 percent in agreement that supply chain management is, indeed, everyone's job. However, we also believe that there is a better way to carry out the practice of making supply chain management a cross-functional responsibility.

The process begins with using smarter metrics—metrics that align quickly and accurately with actual consumer demand and the ability to maintain FLOW across the entire supply chain.

Cost-world metrics must be let go. Retire them completely.

Your company really does not want the lowest possible costs! (You can always reduce your costs to zero by merely closing the doors on your enterprise and going home!)

What your executives and managers should be seeking is the lowest level of costs where FLOW is not disrupted. As Toyota has so ably demonstrated over the last 60 years or so is that this is the real road to sustaining profitability on the long term.

Within Toyota's enterprise, production remains "a black box" to Finance. There are inputs and there are outputs from production, but Finance never meddles with the processes of production in order to "control costs."

A process of ongoing improvement that maximizes FLOW through the elimination of as much non-value-added activity as possible will automatically produce the result of the lowest level of costs without impeding the flow of goods to customers.

Breaking It All Down

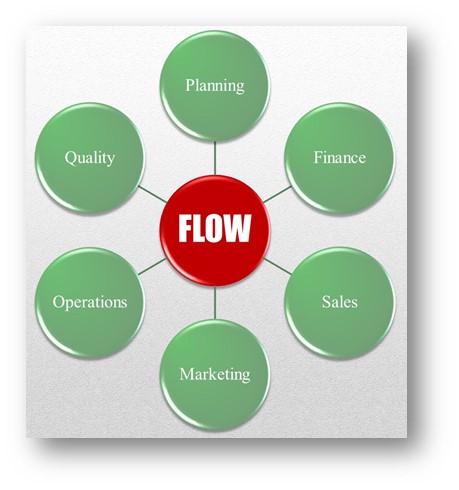

So, let's quickly think—in a general way—about everyone's role in managing the supply chain (based on the illustration above):

- Finance – Change your metrics and stop trying to manage costs. Finance's biggest job—at least early on—is believing that if they stop managing "costs" that profits might actually improve.

- Sales and Marketing – Sales needs to keep the folks in operations and supply chain roles well-informed regarding anticipated upcoming changes in the market conditions that may affect demand (in a positive or negative way). They can also help reduce artificially induced demand variability by changing the way they offer discounts and incentives to customers and/or salespeople. They also need to be able to supply cogent feedback to Operations when internal buffer indicators (i.e., stock buffers, time buffers or capacity buffers) appear to be drifting unexpectedly. They need to able to help the enterprise figure out what is changing as quickly as possible.

- Operations – Operations has the obligation to learn how to measure the right things, while shifting to a more demand-driven system for managing inventories (across the supply chain) and production signals. We strongly recommend moving to Demand Driven MRP or a similar approach.

- Quality – The Quality folks need to work diligently on a POOGI that helps the enterprise build quality in, not sort quality failures out of the FLOW. This is the only way to support FLOW effectively.

- Planning – Planning should become a process of focusing on scaling anticipated changes in future demand (not forecasting numbers to be used for planning production). We call these estimated scales for anticipated changes Planned Adjustment Factors, and they are usually stated as a percent of change. Furthermore, Planning should learn to trust their buffers and the planning and scheduling of purchasing and production will be triggered and managed based on the status of the buffers—not based on forecasts (which are always wrong).

Yes!

Supply chain management is everyone's job. But it is a job that should be carried out cooperatively, systematically, and within a system designed to support a POOGI working toward improving the entire system's ROI and customer service levels.

It should not be carried out erratically with constant oscillation between "cost-saving" and "get the order out the door" mentalities.

We help move our clients in the right direction.

Please, leave your comments below. Let us know how you and your enterprise go about the task of supply chain management. We look forward to hearing from you.