Recently, I read a brief article by Lisa Anderson entitled “Business Process ROI.” I could not help but chuckle at my broad agreement with Anderson when she said that, while she endorsed the concept of “business process improvement,” she was “not a fan of what many term ‘business process improvement’ which turns into a wasted exercise of creating volumes of 1-inch [sic] thick binders of best practice processes that sit on the shelf and collect dust.” [1]

Bravo for that!

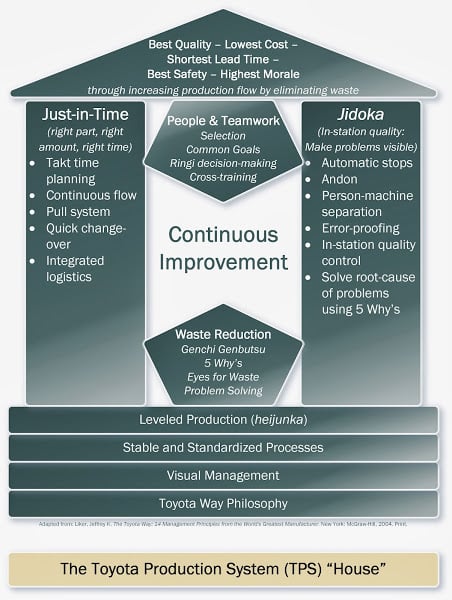

First on the list of Anderson’s tips was “Involve employees” and this immediately reminded me of the Toyota Way and what has come to be known as the Toyota Production System “House” diagram.

Sadly, a great many executives and managers today believe that their ERP (enterprise resource planning) system is the “heart of their enterprise.” People, to these misled managers, are secondary and replaceable components.

Between 1950 and the mid-2000’s, Toyota Motor Company managed to build a worldwide business enterprise which, by 2004, was making more profit than General Motors, Ford and Daimler-Chrysler combined. And its management did, for the most part, without either the computers or the capital available to the Big Three American auto manufacturers.

Involving People

Toyota accomplished this by relying upon people—upon their intuition and upon their innate desire to do a good job.

To this day, Toyota’s manufacturing floor remains, essentially, “a black box” to finance and accounting. Accounting knows the inputs to and outputs from manufacturing operations, but it does not concern itself with measuring “efficiencies” or “utilization.”

The finance department reaps the rewards—the profits—and measures the ROI (return on investment) of a system built on “involving people” in process improvement.

Beginning with the End in View

At Toyota, they begin every thought of “improvement” with the end in view. Their measure of quality is “the entire customer experience” in buying and owning a Toyota product. Therefore, even the profits reaped by Toyota and its supply chain participants do not come from focusing on short-term profits.

Instead, Toyota’s profits are a side-effect, in its view, of creating “fast, flexible processes that give customers what they want, when they want it, at the highest quality and affordable” prices. [2]

Driven by people with a long-term view—and a very successful one at that—Toyota works its supply chain in ways that sometimes seem counterintuitive ways to those caught up in cost-world thinking.

- Often the best thing you can do is to idle a machine and stop producing parts

- Often the best thing you can do is to level-out production rather than attempt to manage according to constantly fluctuating periodic demand

- Often it is best to selectively add and substitute overhead for direct labor, because when you see the real value of value-added workers, you want to support them like you would a surgeon performing a critical operation

- It is not always a top priority to keep your workers busy making parts as fast as possible

- It is best to selectively use information technology and often better to use manual processes, even when automation is available and would seem to justify its cost—because people are more flexible than technology in most cases

The Right Process Will Produce the Right Results

Not long ago, I was helping a client with some production issues that were, believe it or not, being made more complicated and more difficult to manage as a result of the ERP systems the company had in place.

The CEO of the company asked me, “How can we keep our people from taking shortcuts that mess up the data in the [ERP] system?”

I replied, “I believe that your people want to do the right thing. In fact, I think when they take the ‘shortcut’ you describe, that they believe they are doing the right thing. They are serving your customers. They are trying to get the product completed and out the door in order to keep the promises you have made to your customers.

“For these workers, the data in the ERP system is secondary to serving your customers and keeping your promises. And, frankly, when it comes right down to it, I think you believe the same thing.”

The CEO, of course, agreed with me.

What needed to be changed was the process by which the ERP system got its information. Ultimately, it was dramatic simplification of the process that actually improved the flow of production and required no additional personnel.

People Want to Do the Right Thing

When it comes to creating a process of on-going improvement—a POOGI—I tell the companies I work with to begin by listening to what your people are saying.

Toyota has built a worldwide, highly profitable enterprise by listening to its employees. They believe that no one knows more about running the machine—or the process—than the people who actually run it. Managers don’t. Executives don’t.

Start by involving your people. Start by really listening to them.

The same thing goes for listening with an open mind to all of the participants in your supply chain. Toyota does that, too.

It’s a practice worth emulating.

We would be delighted to hear your comments on this or any related topic. Leave your comments below, or feel free to contact us directly, if you prefer.

[1] Anderson, Lisa. "Business Process ROI." Recent Posts. Kinaxis, 21 Nov. 2013. Web. 22 Nov. 2013.

[2] Liker, Jeffrey K. The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer. (p.8) New York: McGraw-Hill, 2004. Print.