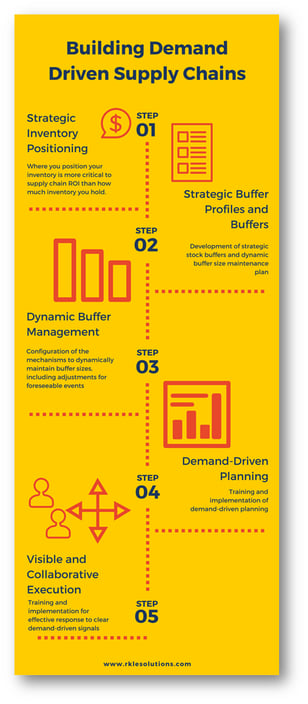

1. Strategic Inventory Positioning

Sadly, far too many supply chain executives and managers are ill-equipped to deal with this first and, probably, most important matter.

Frequently, if the question of inventory positioning is asked at all, it is answered from a purely pragmatic point of view. Strategy seldom enters into the equation.

The strategic positioning of inventory is the most important matter to be addressed when seeking to maximize return on investment for your supply chain inventory dollars.

2. Strategic Buffer Profiles and Levels

The strategic sizing of buffers in also crucial to achieving the highest return on investment from your supply chain dollar.

- Stock-outs and lost sales

- Lost customers

- Increased sales and marketing expenses to replace lost sales and lost customers

- High expediting expenses

- Nearly constant firefighting

- Low morale and higher employee turnover rates.

Too much inventory and expenses increase due to:

- Obsolescence

- Write-offs and write-downs due to excess stock handling and movement

- Low margin liquidations

- Cannibalization of new product sales

- Excess warehousing expenses

- Expenses related to required warehouse expansions or lease of additional storage facilities.

3. Dynamic Buffer Management

Today's supply chains are subject to high levels of volatility. Therefore, to be effective, buffer sizes must dynamically be managed to accommodate changes in market conditions, supplier performance, or other factors.

See also: What is Dynamic Buffer Management?

Many of these factors must be sensed and are not known until after-the-fact. But, other factors may be identified in advance and controlled by business decisions like market promotions, or the opening or closing of new product outlets.

We no longer recommend that firms managing more than 500 SKU-locations try to maintain their inventory buffer sizes manually, as this is increasingly a recipe for ongoing troubles.

4. Demand-Driven Planning

Demand-driven planning shifts the focus from unreliable—read: always wrong—forecasts to planning based on highly reliable signals coming from stock, time and capacity buffers.

Please note that this does not mean that we move our clients to a make-to-order environment. That is simply not feasible in many—even, most—circumstances.

However, it does mean that our clients using demand-driven planning methods have access to relevant information necessary for creating, maintaining, promoting and protecting the FLOW of relevant materials across their supply chains.

5. Highly Visible and Collaborative Execution

By implementing buffer status and synchronization alerts—accompanied by proper training—demand-driven supply chain executives and managers find they are overseeing operations where the FLOW of relevant information is continually supporting and promoting the FLOW of relevant materials up and down their supply chains.

Those involved in the collaborative execution all agree with the meaning of the signals and the priorities set by the signals. Gone are the days of arguing, haggling and compromise only to get the best of the worst solutions, or the worst of the best outcomes.

These five steps—when effectively and conscientiously applied—have demonstrated their ability to deliver dramatic results in as little as twelve weeks following implementation.

If you would like to learn more about becoming truly demand driven, read: DDMRP – Demand Driven Material Requirements Planning

by Carol Ptak and Chad Smith.